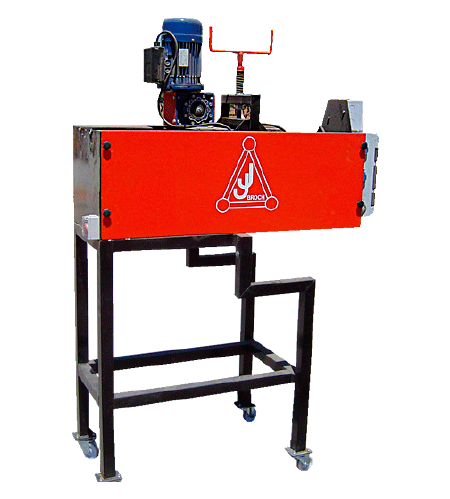

Garlic Splitter

PLANTING & POST HARVEST MACHINERY

Garlic Splitter

Careful splitting and clove selection

The separation and classification of the cloves is the first step for a uniform, regular plantation. High work output allows for the amount shelled to be adapted to the rhythm of the plantation.

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FEEDING HOPPER

The width of the hopper makes unloading the garlic bulbs lifted to the splitter easier, using an adjustable speed belt driven by an electric motor.

SPLITTER

The splitter, equipped with brushes and belts, separates the cloves to prevent pressure and product damage. The position of the belts is adjusted according to the calibre of the cloves.

SELECTION AND SUCTION BELT

Two suction areas remove the remains of any bulbs that cannot be used. Any deformed cloves and those without germinating capacity are removed manually from the belt.

CONCENTRIC GRADER

Healthy, selected cloves are classified into five different calibres using four cylindrical sieves measuring 120 cm in length. A precision classification of the different clove sizes to be sown is achieved from largest to smallest calibre.